The Essential Guide to Shipping Container Dimensions – What You Need to Know

27/03/2024

Shipping containers are standardized containers used for transporting goods via sea, land, or sometimes air. Understanding their dimensions is crucial for efficient logistics planning and cargo management.

As of today, more than 17 million containers of different dimensions and types are used globally to make container shipping the most efficient method of transportation.

The ISO sets the standard shipping container dimensions. These containers are ISO certified, which means they are brought into business only when manufactured and tested per the specifications provided by the International Organization for Standardisation to ensure that the freight is suitable for multiple transportation modes, i.e. via cargo ship, truck or rail.

The ISO Shipping containers must fit perfectly onto ships and lock into chassis and trailers. They also stack perfectly on railcars, saving space and making the transportation of goods easier and more convenient.

The weight of the container is divided into three types:

- the tare weight,

- the gross weight,

- and the payload.

Here’s a comprehensive guide to shipping container dimensions:

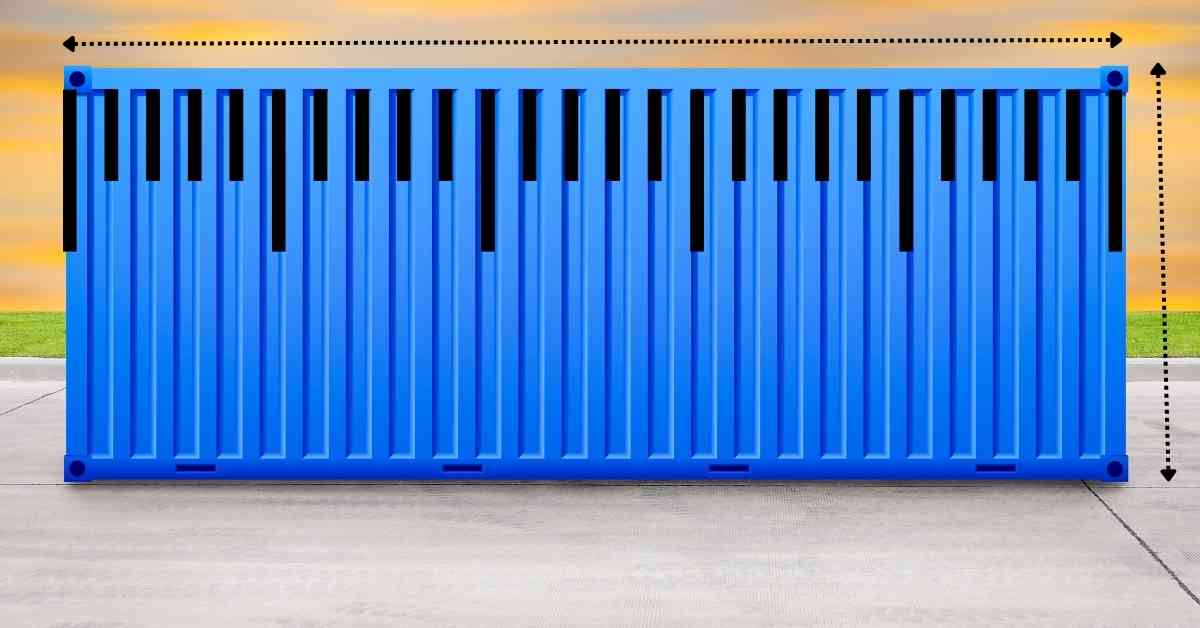

Standard Container Dimensions:

1. 20-foot Container (20ft):

- External Dimensions: 20 feet long, 8 feet wide, and 8 feet 6 inches tall (6.1 meters long, 2.44 meters wide, and 2.59 meters tall).

- Internal Dimensions: Approximately 19 feet 4 inches long, 7 feet 8 inches wide, and 7 feet 10 inches tall (5.9 meters long, 2.35 meters wide, and 2.39 meters tall).

- Capacity: Around 1,170 cubic feet (33.1 cubic meters).

- Maximum Gross Weight: Approximately 52,910 lbs (24,000 kg).

2. 40-foot Container (40ft):

- External Dimensions: 40 feet long, 8 feet wide, and 8 feet 6 inches tall (12.19 meters long, 2.44 meters wide, and 2.59 meters tall).

- Internal Dimensions: Approximately 39 feet 6 inches long, 7 feet 8 inches wide, and 7 feet 10 inches tall (12 meters long, 2.35 meters wide, and 2.39 meters tall).

- Capacity: About 2,390 cubic feet (67.7 cubic meters).

- Maximum Gross Weight: Around 67,200 lbs (30,480 kg).

3. 40-foot High Cube Container (40ft HC):

- External Dimensions: 40 feet long, 8 feet wide, and 9 feet 6 inches tall (12.19 meters long, 2.44 meters wide, and 2.89 meters tall).

- Internal Dimensions: Approximately 39 feet 6 inches long, 7 feet 8 inches wide, and 8 feet 10 inches tall (12 meters long, 2.35 meters wide, and 2.69 meters tall).

- Capacity: Approximately 2,694 cubic feet (76.3 cubic meters).

- Maximum Gross Weight: About 67,200 lbs (30,480 kg).

4. 45-foot Container (45ft):

- External Dimensions: 45 feet long, 8 feet wide, and 9 feet 6 inches tall (13.7 meters long, 2.44 meters wide, and 2.89 meters tall).

- Internal Dimensions: Approximately 44 feet 6 inches long, 7 feet 8 inches wide, and 8 feet 10 inches tall (13.56 meters long, 2.35 meters wide, and 2.69 meters tall).

- Capacity: Roughly 3,040 cubic feet (86.1 cubic meters).

- Maximum Gross Weight: Typically around 65,900 lbs (29,900 kg).

Benefits and Usage:

Increased Capacity: Compared to the standard 40-foot container, the 45-foot container offers additional space, making it suitable for larger cargo volumes or bulkier items.

Efficiency: Utilizing 45-foot containers can enhance efficiency by reducing the number of containers needed for shipping large quantities of goods.

Flexibility: Some transportation routes or terminals may specifically accommodate 45-foot containers, offering greater flexibility in logistics planning.

Cargo Types: These containers are suitable for a wide range of cargo types, including general goods, machinery, equipment, and bulk commodities.

Considerations:

Availability: While 45-foot containers are increasingly common, they might not be as readily available as standard 20-foot and 40-foot containers in certain regions or shipping routes.

Transportation Costs: Due to their larger size and weight, transportation costs for 45-foot containers may be higher compared to standard containers.

Handling Equipment: Ensure that ports, terminals, and transportation providers have the necessary equipment to handle and transport 45-foot containers safely and efficiently.

By considering the dimensions and benefits of a 45-foot container, you can determine whether it’s suitable for your shipping needs and optimize your logistics operations accordingly.

Other Container Types:

Flat Rack Containers: These containers have collapsible sides, enabling easy loading of oversized cargo.

Open Top Containers: Similar to standard containers but with a removable top, facilitating top-loading of cargo.

Refrigerated Containers (Reefers): These containers are equipped with refrigeration units for transporting temperature-sensitive goods.

Tank Containers: Designed for transporting liquids, gases, or powders in bulk.

Specialty Containers: Tailored containers for specific cargo types, such as vehicles, livestock, or hazardous materials.

Considerations for Container Shipping:

Cargo Size and Weight: Ensure your cargo fits within the dimensions and weight limits of the chosen container type.

Container Condition: Inspect containers for any damage or defects before loading to prevent damage to goods during transit.

Loading and Securing: Properly load and secure cargo within containers to prevent shifting or damage during transport.

Regulatory Compliance: Adhere to international shipping regulations and safety standards applicable to your cargo type.

By understanding shipping container dimensions and types, you can effectively plan and manage your logistics operations, ensuring efficient and secure transportation of goods worldwide.

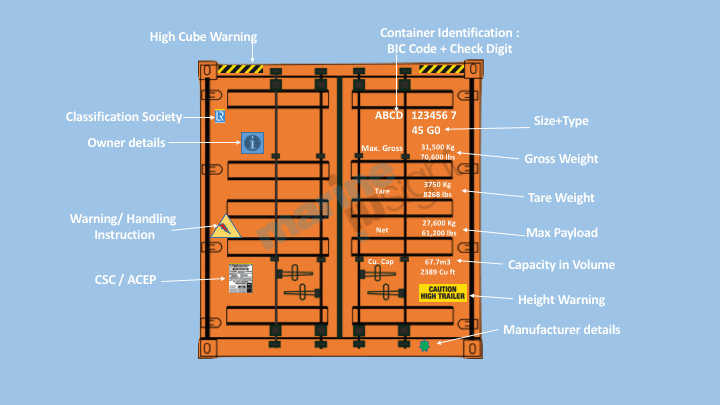

Markings on a shipping container

Shipping containers typically bear various markings that convey important information about their contents, handling, and specifications. These markings are standardized to ensure efficient handling and safe transportation across different logistics networks. Here are some common markings found on shipping containers:

ISO Code and Identification Number: Every shipping container is assigned a unique identification number, typically referred to as the Container Number or Box Number. This alphanumeric code is preceded by an ISO 6346 reporting mark, indicating the country code, owner code, serial number, and check digit. For example, “MSCU 123456 7.”

Tare Weight: The weight of an empty container is indicated near the container’s doors. This allows for easy calculation of the net weight of cargo being loaded.

Max Gross Weight: The maximum gross weight the container can carry, including cargo and container weight, is displayed on the container’s exterior. Exceeding this weight limit is a safety hazard and can lead to penalties.

Payload Capacity: The maximum weight of the cargo the container can safely carry is often specified alongside the maximum gross weight.

Size and Type Designation: The size and type of the container are prominently displayed on the exterior. Common sizes include 20-foot (20′), 40-foot (40′), and 45-foot (45′) containers. Variations such as “High Cube” or specialized containers like refrigerated (reefers) are also labeled accordingly.

Safety and Handling Marks: Symbols indicating handling instructions, such as “This Side Up,” “Handle with Care,” or “Keep Dry,” are often present to guide port workers and freight handlers in the proper handling of the container.

Owner and Operator Information: The name, logo, and contact information of the container’s owner or operator may be displayed on the container’s exterior for identification and tracking purposes.

Approval and Certification Marks: Containers are typically manufactured and certified to international standards such as those set by the International Convention for Safe Containers (CSC). Certification marks and approval seals indicate compliance with safety and quality standards.

Hazardous Material Labels: Containers carrying hazardous materials or dangerous goods must display appropriate hazard labels and placards according to international regulations such as the International Maritime Dangerous Goods (IMDG) Code.

Ventilation and Refrigeration Markings: Containers equipped with ventilation or refrigeration systems may have corresponding markings indicating airflow requirements, temperature settings, or refrigerant types.

These markings serve to ensure the safe and efficient handling, transportation, and tracking of shipping containers and their contents throughout the global supply chain.

Source: internet