A very simple explanation for the term transit time is that – it is the time or the number of days taken for a consignment to move from point A to point B. In shipping terminology, this is referred to as transit time or transit days.

It is an important factor affecting businesses and any other operations that procure raw materials, parts, or finished goods from suppliers to be reprocessed, repackaged, or simply redistributed.

Generally referred to as raw materials, these items are shipped by suppliers based on purchase orders from the customer, using a convenient and economical mode of transport as agreed between the two.

Why is transit time important? Without receiving raw materials, finished goods, or parts from their suppliers on time, any business will not be able to operate. They will not be able to meet their commitments to their customers.

Transit time is an important component of lead time. In business, lead time is the total time taken to realize a purchase order placed with a supplier.

It is a measure of the total time taken from the moment a purchase order is placed with a supplier till the goods are received at the purchaser’s warehouse.

Lean Business Models and Lead Time

Lean business models operate on a strict policy of waste elimination and cost reduction. In the current competitive business environment, most organizations operate on lean business models.

What are lean business models? A lean business model is all about minimizing or eliminating waste within an organization. This results in increased customer satisfaction and ultimately the profitability of the organization.

Companies that follow the lean business model achieve their objective by focusing on improvement and optimization of their processes and increasing the knowledge base of their employees, thereby reducing costs.

Here, the lead times of the required materials play an important role. Variations in transit time affect the lead time. Fluctuating lead times can make purchase order forecasting difficult and unrealistic. Without getting the raw materials at the right time, companies cannot meet their deadlines.

When raw materials are received earlier than required, it takes up storage space and also results in unnecessary stockholding for the company.

Any delay in the receipt of raw materials would affect the processing or production cycle. It might result in stock-outs that affect the timely delivery of goods to customers.

Just-In-Time (JIT) is an inventory management concept in which material and labour for manufacturing are arranged to arrive only when required and just in time for the manufacturing process.

Lead Time and Transit Days

Lead Time and Transit Days

Typically, the breakup of lead time is as follows:

Total Lead Time = Goods ready days + Transit days + Clearance and delivery days

Goods ready days (GRD) is calculated as the number of days taken from the time of placing a purchase order with a supplier to the time it is available to the transporter for shipment.

The supplier has to have the goods ready as agreed with the buyer and transporter. However, there may be delays from the supplier’s end in readying the goods.

Production bottlenecks, issues with packing and labelling, or incomplete export formalities and documentation can cause delays.

Unexpected delays from the supplier’s side may result in the cargo missing its sailing. If it is a transhipment cargo there is a very likely chance of it missing all the subsequent sailings from the other ports.

Sometimes a purchase order may consist of different goods from different sources that may have to be consolidated by the supplier. Delay in consolidation can upset the delivery deadline that has been agreed with the transporter.

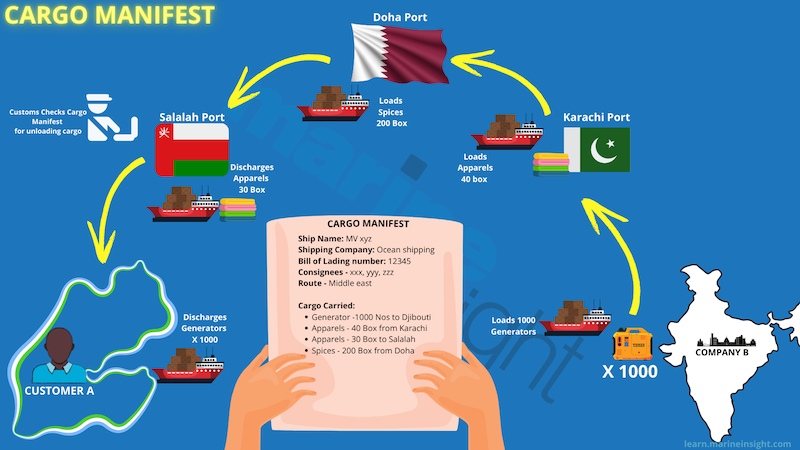

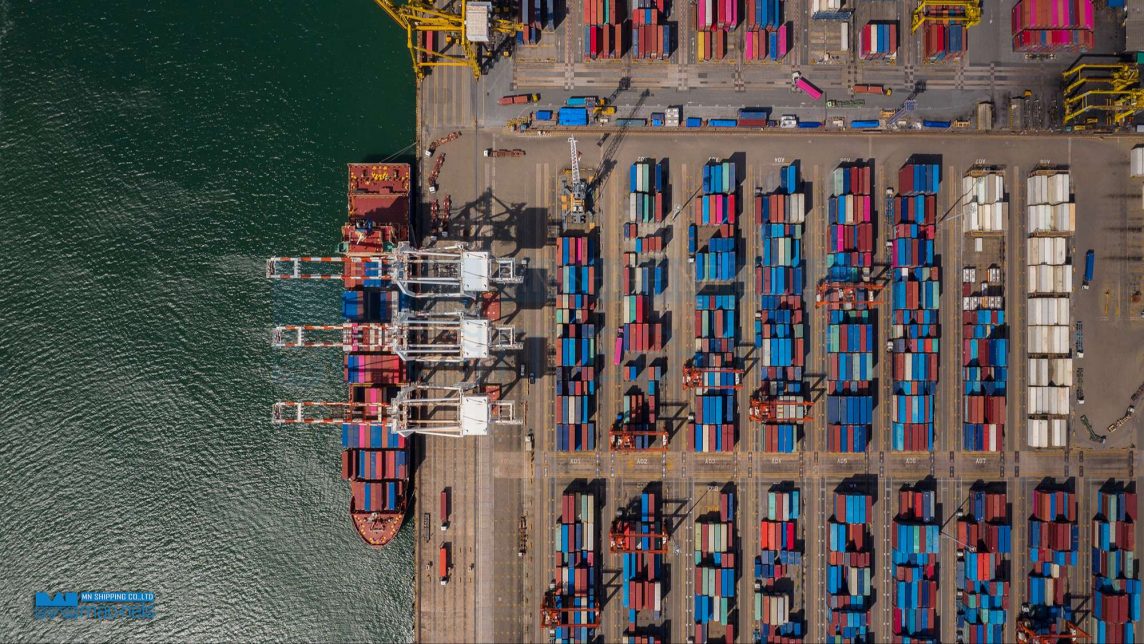

Transit days (TD) is the number of days taken from when the goods are picked up from the supplier by the transporter, till it is discharged at the destination port.

Transit days include the time taken to move it from the supplier’s warehouse to the port of origin, storage days at the port if any, the sailing time, and finally, the time taken to discharge the cargo at the destination port, ready for customs clearance.

The number of days it takes for customs clearance of the goods and their delivery to the customer’s premises is the clearance and delivery days (CDD).

A simple example of the breakup of lead time by its different components is given below.

The Techstart company in Chennai, India places a purchase order for 20 pieces of machinery with Yamaguchi & Sons, Yokohama, Japan on 25 June. As agreed between both companies, the number of days to ready this order is 10 days.

On 5 Jul, the transporter picks up these 20 units and puts them in a 20’ GP container, and moves it to the port of Yokohama. It is booked by vessel MV Marijan that sets sail on the 7 Jul. The sailing time is 19 days from Yokohama to Chennai.

The vessel berths at Chennai port on 26 July and the goods are discharged the same day. Customs clearance takes another 3 days and the container is transported to the warehouse of Techstart company on 29 July.

The number of days taken for each component is as follows:

| Goods Ready Days (GRD) | Transit Days (TD) | Clearance & Delivery Days (CDD) | Total Lead Time Days (LTD) |

| 25 Jun – 5 Jul | 5 – 7 Jul + 7 – 26 Jul | 26 – 29 Jul | 25 Jun – 29 Jul |

| 10 | 2+19 | 3 | 34 |

Forecasting

Forecasting is the technique of predicting future demands by using historic data. Different organizations use different forecasting models to arrive at the demand quantities.

The 2 main types of forecasting are quantitative forecasting and qualitative forecasting. Quantitative forecasting makes use of historical data to calculate future demands while qualitative forecasting makes use of judgment based on past or recurring events.

In qualitative forecasting, numerical data is not used for working out future demands and it relies heavily on experienced and knowledgeable company staff or forecasters.

Lead time is critical in forecasting and it is used to work out the optimum order quantities. Forecasters and planners have to consider the different factors that may cause delays to their orders and arrive at the purchase order figures accordingly. Maintaining an optimum buffer stock to tide over such emergencies is one option available to forecasters and planners.

Factors Affecting Transit Time

Several factors affect the transit time of goods.

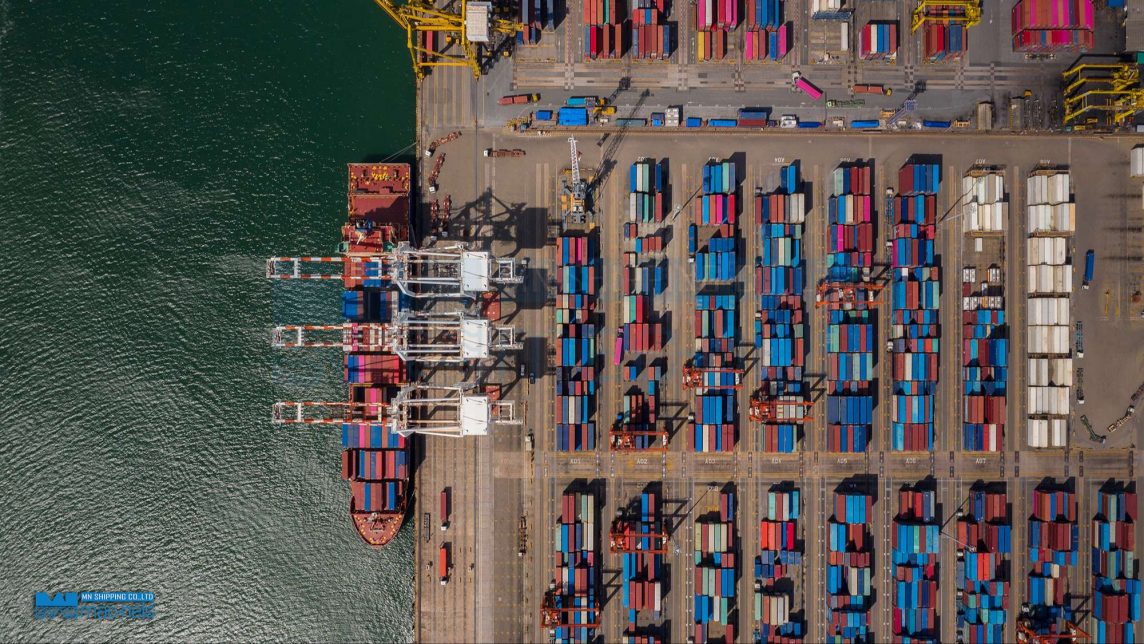

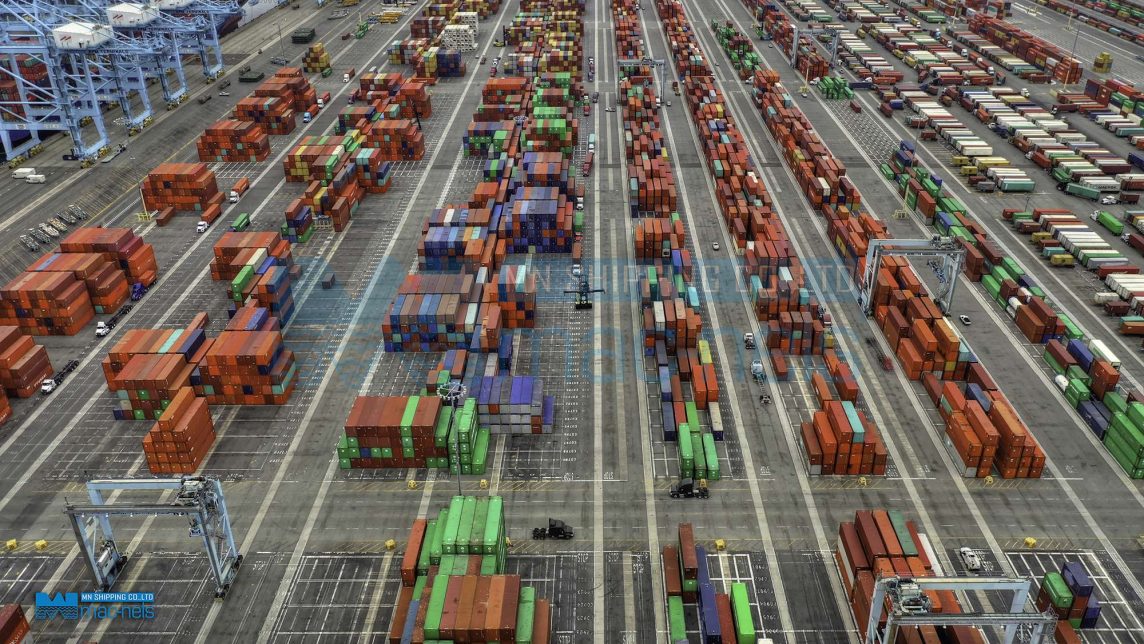

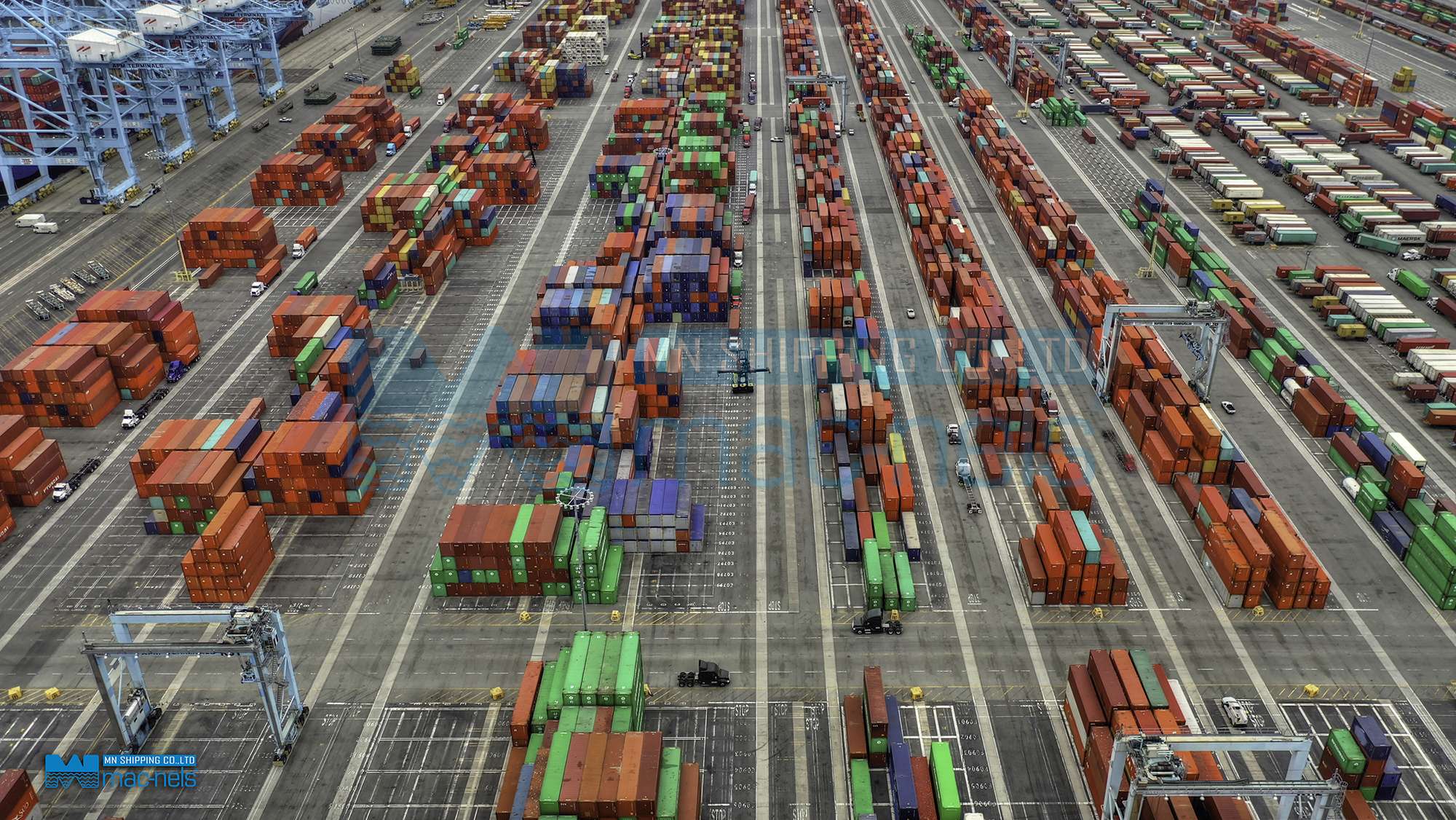

Port terminals usually have their woes which in turn may affect the transit time of vessels. Inadequate handling equipment at ports, equipment breakdown, and labour problems are just some of these.

Any of these problems can result in delays to vessels, whether incoming or waiting to set sail. Delays affect the loading and unloading of cargo.

Blank sailing of a cargo vessel can upset the loading and unloading of cargo at these ports. What is blank sailing? Blank or void sailing is when a ship does not call at a scheduled port.

It could be a single port that is omitted or more than one, in the string. All the ports that are covered by the ship during its voyage are called a string.

Blank sailing affects all the cargo waiting to get loaded onboard the ship from the port or ports. Cargo that could not be loaded will have to take the next available sailing. It results in extended transit time.

It affects unloading too. When a ship skips a port, the cargo that should have been offloaded at that port is discharged at the next port of call. Once again, the transit time is stretched. For more details on blank sailing please read the article available on the following link:

Transit time can be affected by port congestions when the ship is not able to get a berthing slot. Bad weather or changes to the vessel’s sailing schedule can also affect transit time.

Forecasters and planners have to consider all the various factors and plan accordingly. These factors include weather conditions at origin and enroute, holidays and seasonal market closures, etc.

Customs clearance of cargo after it is discharged at the destination port must be planned well. Discrepancies or errors in documentation, failure to arrange the necessary labour and transport, etc. can unnecessarily extend the lead time.

Reference: Marine Insight

Because of the design and insulation materials used in the construction of reefers their internal dimensions are much less than normal dry vans or TEU.

Because of the design and insulation materials used in the construction of reefers their internal dimensions are much less than normal dry vans or TEU.